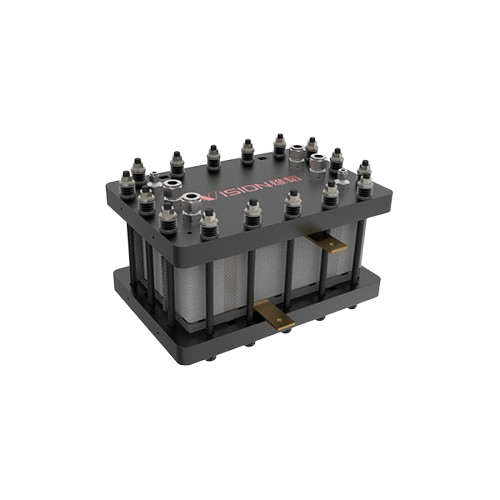

Hydrogen Full CellElectrolyzerDifferential Pressure PEM High-Pressure Electrolyzer

Differential Pressure PEM High-Pressure Electrolyzer

-

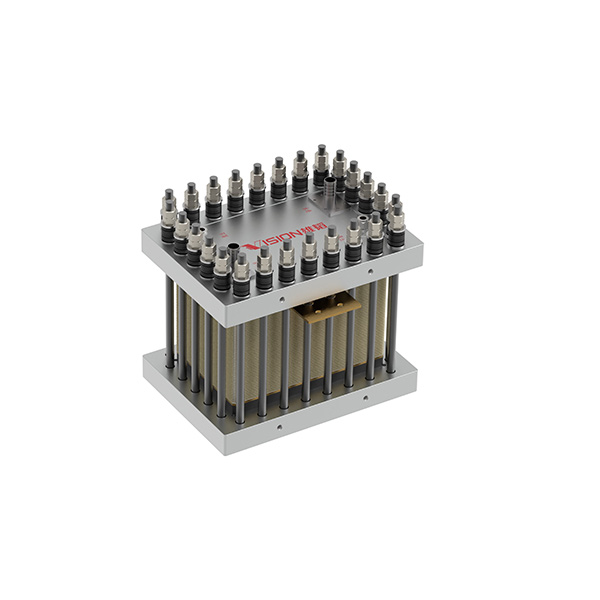

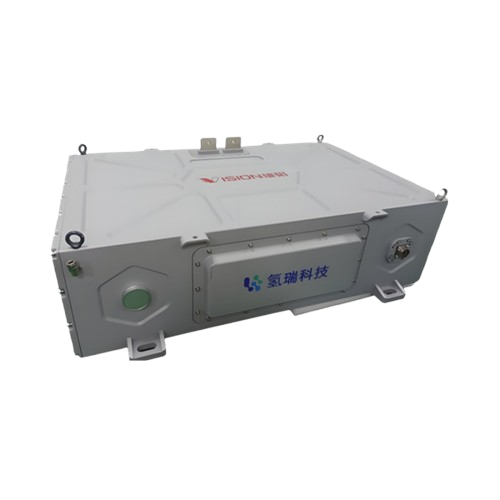

Overview:Independently developed 10 N/m³ differential pressure PEM high-pressure electrolyzer, capable of withstanding pressure differentials up to 3 MPa, ensuring safety and reliability. It achieves zero leakage and zero explosion risk even under extreme operating conditions. The system’s DC power consumption is reduced to 4.2 kWh/Nm³. With breakthroughs in critical core components that overcome key technology bottlenecks, this electrolyzer is fully self-controlled and sets a new benchmark for safe and efficient hydrogen production.

-

Application Scenarios:Renewable Energy Integration

Industrial High-Pressure Hydrogen Supply

Transportation Energy Innovation

Key Features

-

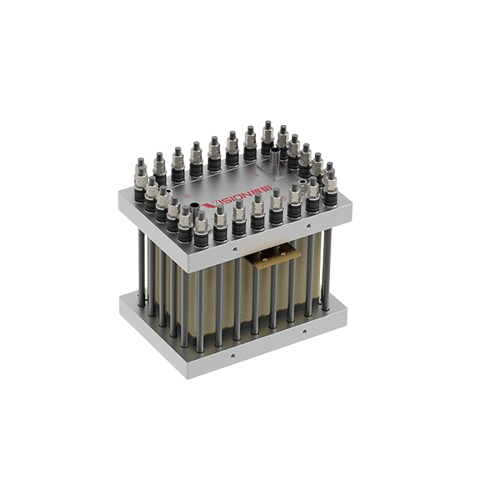

Safety First, Performance at the Core — Ultimate Safety with Multiple Redundant Protections1. Innovatively adopts domestically-produced high-performance membrane electrode assemblies (MEAs) and multi-layer redundant sealing design, enabling stable hydrogen production at 3 MPa high pressure with a zero-leakage guarantee under extreme conditions.

2. Passed rigorous small-scale stack testing covering pressure shocks and long-term operation under complex conditions, ensuring high safety and reliability. -

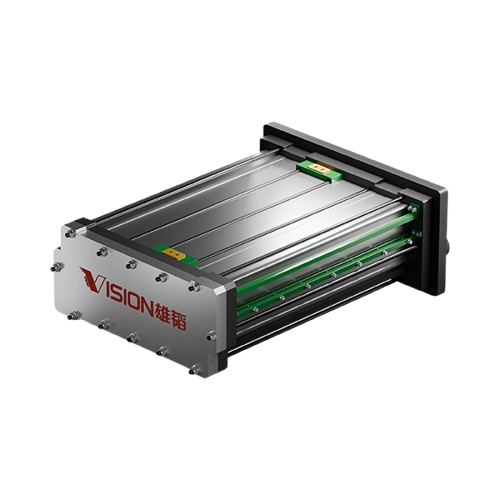

High Efficiency, Low Energy Consumption1. Industry-leading efficiency at 1.75 V @ 2.0 A/cm², with optimized flow fields and catalyst layers, reducing electrolytic energy consumption and cutting hydrogen production costs by over 15%.

2. Direct high-pressure supply at 3 MPa improves system efficiency by 20%, achieving cost and efficiency gains across the entire value chain. -

Localization Breakthrough, Fully Independent Control1. Core components such as membrane electrodes and sealing assemblies are 100% domestically produced, breaking technological monopolies and ensuring supply chain security.

2. Custom development capabilities adapt to diverse scenarios, from distributed energy to industrial-scale hydrogen production, flexibly meeting customer demands.

Industry Applications

NEED HELP FINDING THE BEST SOLUTION?

Submit our form and we'll prioritize it.

-

Name

Name -

Tel

Tel -

Email

Email -

CountryPlease selectAfghanistan Albania Algeria Andorra Angola Antigua and Barbuda Argentina Armenia Australia Austria Azerbaijan Bahamas Bahrain Bangladesh Barbados Belarus Belgium Belize Benin Bhutan Bolivia Bosnia and Herzegovina Botswana Brazil Brunei Bulgaria Burkina Faso Burundi Cabo Verde Cambodia Cameroon Canada Central African Republic Chad Chile China Colombia Comoros Congo (Congo-Brazzaville) Costa Rica Croatia Cuba Cyprus Czech Republic (Czechia) Democratic Republic of the Congo Denmark Djibouti Dominica Dominican Republic Ecuador Egypt El Salvador Equatorial Guinea Eritrea Estonia Eswatini Ethiopia Fiji Finland France Gabon Gambia Georgia Germany Ghana Greece Grenada Guatemala Guinea Guinea-Bissau Guyana Haiti Honduras Hungary Iceland India Indonesia Iran Iraq Ireland Israel Italy Jamaica Japan Jordan Kazakhstan Kenya Kiribati Kuwait Kyrgyzstan Laos Latvia Lebanon Lesotho Liberia Libya Liechtenstein Lithuania Luxembourg Madagascar Malawi Malaysia Maldives Mali Malta Marshall Islands Mauritania Mauritius Mexico Micronesia Moldova Monaco Mongolia Montenegro Morocco Mozambique Myanmar (Burma) Namibia Nauru Nepal Netherlands New Zealand Nicaragua Niger Nigeria North Korea North Macedonia Norway Oman Pakistan Palau Palestine Panama Papua New Guinea Paraguay Peru Philippines Poland Portugal Qatar Romania Russia Rwanda Saint Kitts and Nevis Saint Lucia Saint Vincent and the Grenadines Samoa San Marino Sao Tome and Principe Saudi Arabia Senegal Serbia Seychelles Sierra Leone Singapore Slovakia Slovenia Solomon Islands Somalia South Africa South Korea South Sudan Spain Sri Lanka Sudan Suriname Sweden Switzerland Syria Taiwan Tajikistan Tanzania Thailand Timor-Leste Togo Tonga Trinidad and Tobago Tunisia Turkey Turkmenistan Tuvalu Uganda Ukraine United Arab Emirates United Kingdom United States Uruguay Uzbekistan Vanuatu Vatican City Venezuela Vietnam Yemen Zambia Zimbabwe

CountryPlease selectAfghanistan Albania Algeria Andorra Angola Antigua and Barbuda Argentina Armenia Australia Austria Azerbaijan Bahamas Bahrain Bangladesh Barbados Belarus Belgium Belize Benin Bhutan Bolivia Bosnia and Herzegovina Botswana Brazil Brunei Bulgaria Burkina Faso Burundi Cabo Verde Cambodia Cameroon Canada Central African Republic Chad Chile China Colombia Comoros Congo (Congo-Brazzaville) Costa Rica Croatia Cuba Cyprus Czech Republic (Czechia) Democratic Republic of the Congo Denmark Djibouti Dominica Dominican Republic Ecuador Egypt El Salvador Equatorial Guinea Eritrea Estonia Eswatini Ethiopia Fiji Finland France Gabon Gambia Georgia Germany Ghana Greece Grenada Guatemala Guinea Guinea-Bissau Guyana Haiti Honduras Hungary Iceland India Indonesia Iran Iraq Ireland Israel Italy Jamaica Japan Jordan Kazakhstan Kenya Kiribati Kuwait Kyrgyzstan Laos Latvia Lebanon Lesotho Liberia Libya Liechtenstein Lithuania Luxembourg Madagascar Malawi Malaysia Maldives Mali Malta Marshall Islands Mauritania Mauritius Mexico Micronesia Moldova Monaco Mongolia Montenegro Morocco Mozambique Myanmar (Burma) Namibia Nauru Nepal Netherlands New Zealand Nicaragua Niger Nigeria North Korea North Macedonia Norway Oman Pakistan Palau Palestine Panama Papua New Guinea Paraguay Peru Philippines Poland Portugal Qatar Romania Russia Rwanda Saint Kitts and Nevis Saint Lucia Saint Vincent and the Grenadines Samoa San Marino Sao Tome and Principe Saudi Arabia Senegal Serbia Seychelles Sierra Leone Singapore Slovakia Slovenia Solomon Islands Somalia South Africa South Korea South Sudan Spain Sri Lanka Sudan Suriname Sweden Switzerland Syria Taiwan Tajikistan Tanzania Thailand Timor-Leste Togo Tonga Trinidad and Tobago Tunisia Turkey Turkmenistan Tuvalu Uganda Ukraine United Arab Emirates United Kingdom United States Uruguay Uzbekistan Vanuatu Vatican City Venezuela Vietnam Yemen Zambia Zimbabwe -

Company

Company

Information

InformationWe collect your information (name, email, company) to respond to your inquiry and send marketing emails. You can unsubscribe or request deletion at any time. By submitting, you agree to our Privacy Policy.

I agree to receive marketing emails and accept the Privacy Policy.