Vision Technology

Committed to continuous R&D, dedicated to creating excellence

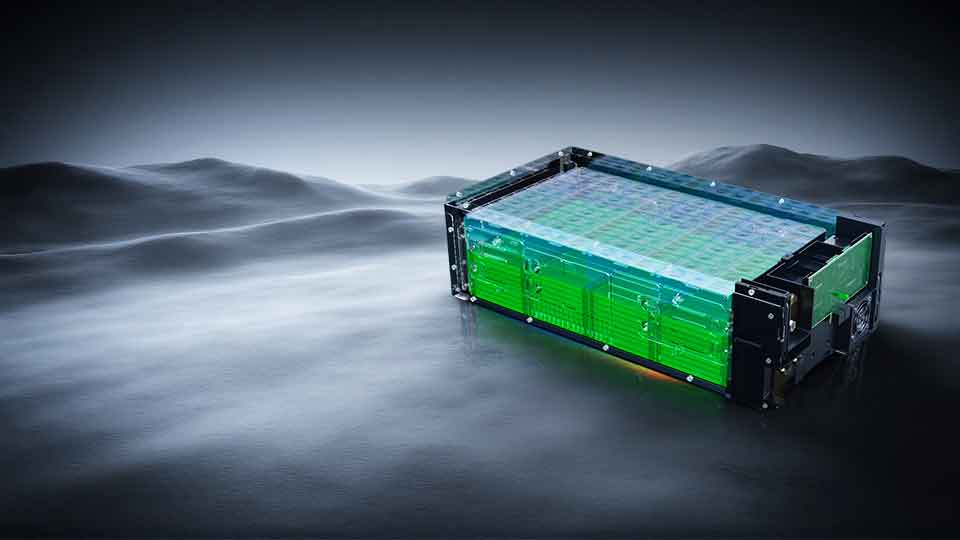

Liquid Cooling Technology for UPS Lithium Battery Systems

Release Date2025.08.06

To improve system stability and battery lifespan, Vision has adopted advanced liquid cooling technology in UPS lithium battery systems. Compared with traditional air cooling, liquid cooling offers higher heat exchange efficiency, effectively controlling cell temperature differences and preventing local overheating. It is especially suitable for high power density, 24/7 data center operations.

Advantages

High Cooling Efficiency

Higher heat exchange efficiency quickly removes heat, ensuring stable operating temperatures.

Extended Lifespan

Balanced temperatures slow down cell aging, extending overall system life.

Enhanced Safety

Prevents local overheating and reduces thermal runaway risk, greatly lowering fire hazards.

Space Saving

Smaller cooling components are ideal for high-density deployments in server rooms.

Active Balancing Technology

Release Date2025.07.06

The active balancing technology applied in the REVO 3.0 UPS backup power system dynamically balances multiple individual cells within the battery pack. This maximizes the overall capacity of the battery system, ensures cell consistency, enhances overall performance, extends battery lifespan, and improves system efficiency.

Advantages

Reduced Energy Waste

With a maximum balancing current of ≤3A, REVO 3.0 improves energy utilization within the battery pack, significantly reducing energy loss.

Extended Battery Lifespan

By maintaining cell consistency throughout the lifecycle, the system prevents performance degradation caused by imbalance and greatly extends battery life.

Enhanced Safety

Minimizing inconsistencies among cells lowers the risk of safety incidents, ensuring reliable and secure power supply for data centers.

Improved System Efficiency

Active balancing enhances overall battery pack performance, enabling high-efficiency operation of the UPS backup system and stable power support for data centers.

Maximized Battery Capacity

By optimizing the charging and discharging process, active balancing ensures full utilization of the battery pack’s capacity.

Increased Cell Consistency

This technology reduces performance differences between individual cells, ensuring uniformity across the battery pack.

Vision Solid-State Battery Technology

Release Date2025.04.02

Safety is the lifeline of the energy industry. To tackle this critical challenge, Vision is driven by technological innovation. Building on 30 years of expertise, the newly developed 60Ah solid-state battery achieves a dual breakthrough in safety and performance through two core technologies.

Advantages

Innovative In-situ Polymerization Process

Electrolyte forms inside the battery, ensuring stable structure and strong compatibility.

Superior Interface Contact

Dynamic film-forming technology seamlessly wraps active electrode particles, significantly reducing interface impedance.

Outstanding High-Rate Performance

Supports continuous discharge from 1C to 10C, 5C pulse charging, and 12C pulse discharge to meet fast response needs in various scenarios.

Versatile Application Compatibility

Balances safety and high performance, ideal for energy storage, electric mobility, and other demanding fields.

Flame Retardant Technology

Release Date2025.07.22

Vision's self-developed flame retardant technology improves lithium cell safety with three layers of protection: a coated separator, flame-retardant additives in the electrolyte, and a special current collector design. During thermal runaway, it slows heat spread, stops combustion, and cuts off current automatically—significantly lowering the risk of fire or explosion. This technology is already used in Vision's 60Ah 10C high-rate lithium cell.

Advantages

Triple Safety Protection

Coated separator, flame-retardant electrolyte, and fuse-structured tabs work together to ensure multi-level safety

Thermal and Oxygen Barrier

The coated separator forms an insulating, oxygen-resistant layer at high temperatures to delay heat spread

Combustion Suppression Mechanism

Electrolyte additives release radical quenchers under heat to interrupt chain combustion reactions

Automatic Overcurrent Cut-off

Fuse-inspired tab design disconnects the circuit in case of abnormal current, preventing escalation

Enhanced Intrinsic Safety

Provides effective self-protection without relying on external safety devices

Field-Proven Reliability

Successfully implemented in 60Ah 10C high-rate cells, with outstanding safety performance validated in use

High-Power Lithium Cell Technology

Release Date2025.08.06

Vision’s high-power lithium cell technology builds a superconductive network and fast-ion channels to greatly enhance power output. The cross-arranged full-tab structure significantly reduces internal resistance and heat generation, improving current transmission efficiency and optimizing module design. This technology has been successfully applied to 50Ah 10C high-rate lithium cells, ideal for applications requiring high instantaneous power.

Advantages

Full-Tab Structure Design

Cross-tab layout lowers internal resistance, improves current distribution uniformity, and reduces local heating.

Lower Heat Generation

Smaller internal resistance and balanced current flow reduce energy loss and heat buildup.

Simplified Structure

Same-side tabs simplify PACK design, reducing system complexity and assembly cost.

High-Rate Discharge Ready

Applied in 50Ah 10C cells with stable and reliable performance.

100% Increase in Power Density

Superconductive network and fast-ion channels work together for efficient dual-path transmission.

Large-Capacity Long-Cycle Lithium Cell Technology

Release Date2025.08.06

Through multi-dimensional optimization of cathode, anode, and electrolyte systems, Vision has developed large-capacity lithium cell technology with extended service life. The cathode incorporates lithium replenishment to increase active lithium content, while the anode uses magnetization technology to improve interface structure. A dual-electrolyte injection process enhances electrolyte permeability and SEI film stability. These synergistic innovations improve cycle life by over 8%. The technology has been successfully applied to 348Ah large-capacity energy storage lithium cells.

Advantages

Lithium Replenishment for Higher Usable Lithium

Cathode lithium replenishment improves cycle performance by 3–5% and slows capacity fade.

More Stable Anode Interface

Magnetization shapes the anode structure, extending cycle life by about 3.5%.

Dual-Electrolyte Injection Process

Improves electrolyte permeability, enhances SEI film density and stability, extending cycle life by about 1.5%.

Designed for Long-Life Energy Storage

Successfully applied to 348Ah large-capacity lithium cells for large-scale energy storage systems.

Over 8% Longer Cycle Life

Coordinated optimization of cathode, anode, and electrolyte systems significantly extends cell lifespan.

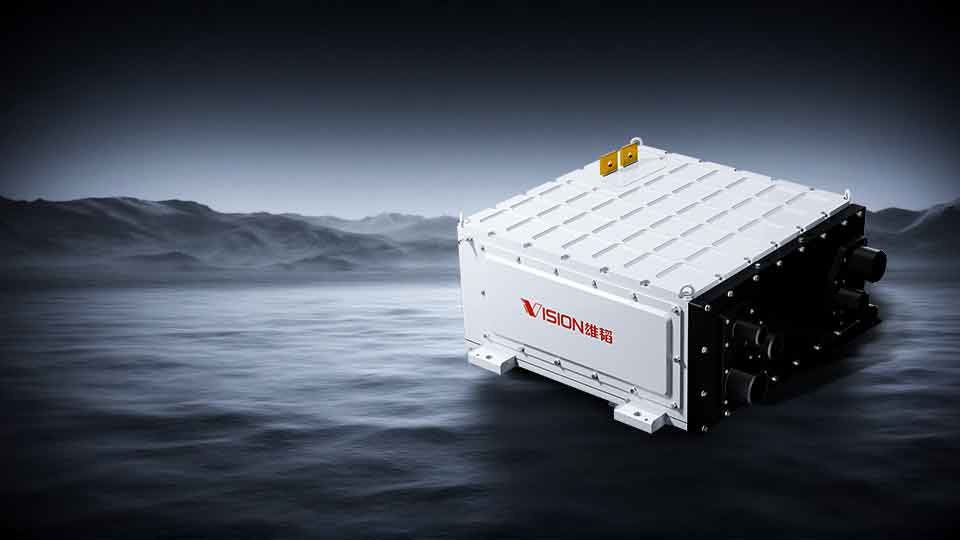

Metal Stack Technology

Release Date2025.08.06

Vision’s metal stack technology combines single-cell structural innovation with optimized metal materials to deliver a highly recyclable, lightweight, and high stacking-efficiency fuel cell stack solution. It adopts the world’s first detachable integrated single-cell design, paired with ultra-thin titanium bipolar plates and integrated cathode self-humidification technology, enhancing system reliability and energy efficiency. This technology has been successfully applied to the W1.5T titanium plate metal stack product.

Advantages

World's First Detachable Single-Cell Design

Bipolar plates and MEAs can be recycled and reused, reducing maintenance and replacement costs.

No Weld Corrosion Risk

Eliminates corrosion issues from welded metal bipolar plates, improving lifespan and stability.

Efficient Failure Screening

Enables quick diagnosis and replacement of faulty cells, improving stack consistency and maintenance efficiency.

Ultra-Light Titanium Design

Titanium’s density is only 56% of stainless steel, significantly reducing weight for applications with high lightweight requirements (e.g., automotive).

Lower System Energy Consumption

Reduced load and higher stacking efficiency improve overall system energy performance.

Cathode Self-Humidification

Maintains humidification across the full power range, reducing the need for separate humidifiers, simplifying design, and increasing reliability.

Proven in Mass Production

Successfully applied in W1.5T titanium plate metal stacks with outstanding performance.

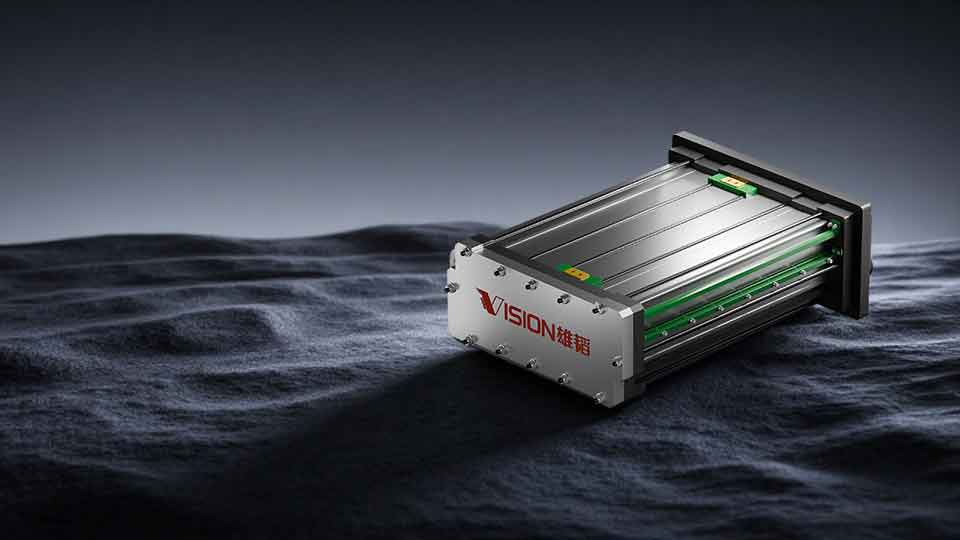

Paper Stack Technology

Release Date2025.08.06

Vision’s paper stack technology uses advanced carbon fiber composite materials to overcome the weight, lifespan, and safety limitations of traditional graphite and metal stacks. Featuring lightweight carbon composite bipolar plates, highly corrosion-resistant structures, and an integrated conductive–insulating design, it delivers next-generation fuel cell stacks with high power density, long lifespan, and exceptional safety. This technology has been successfully applied to the P2 paper stack, suitable for demanding applications such as aerospace propulsion, distributed energy, and heavy-duty transportation.

Advantages

Lightweight Plate Design

Carbon fiber–resin composite plates are 40% lighter than traditional graphite plates, significantly reducing weight.

High Power Density Output

Power density reaches 5 kW/L, breaking the “heavy and inefficient” limits of conventional graphite stacks.

Ideal for Space/Weight-Constrained Applications

Perfect for aircraft propulsion systems, distributed energy stations, and other weight-sensitive scenarios.

Ultra-Long Lifespan

Gradient densification improves carbon fiber corrosion resistance, extending stack life beyond 30,000 hours.

Excellent Corrosion Resistance

Chemical resistance is 50% higher than traditional metal plates, with performance decay ≤ 0.8% per 1,000 hours under all conditions.

Safe Conductive Structure Design

Conductive–insulating composite plates precisely control conductive areas, achieving 99% short-circuit suppression efficiency.

Strong High-Load Adaptability

Performs reliably in long-duration, high-intensity, and complex environments such as heavy transport and off-grid power.

Proven in Industrial Applications

Successfully applied in the P2 paper stack with stable, safe, and reliable performance.

Graphite Stack Technology

Release Date2025.08.06

Vision’s graphite stack technology is designed for high-efficiency power generation and heavy-duty applications, combining high power output, ultra-long lifespan, modular scalability, and integrated structural innovations. Upgraded plate materials and stack design significantly improve power density and system consistency, while built-in self-humidification and integrated end plate functions expand its application to hydrogen energy storage, data centers, heavy trucks, ships, and rail transit. The technology has been successfully applied in A1H and A2 graphite stack products.

Advantages

High Efficiency & Ultra-Long Lifespan

A2 series delivers 150–178 kW per stack with up to 63% power generation efficiency and over 40,000 hours of design life.

20% Higher Power Density

Stronger output per unit volume and improved system integration efficiency compared with the previous generation.

25% Cost Reduction

Optimized technology reduces material and structural costs, enhancing overall cost performance.

Modular Expansion Design

Easily scalable to MW-level systems, suitable for hydrogen storage and large-scale power generation.

High Power Output Capability

Supports up to 200 kW per stack for heavy-duty scenarios such as data centers, heavy trucks, ships, and rail transit.

Self-Humidification Technology

Moisture-retaining plate flow channels combined with matched carbon paper enable cathode self-humidification, eliminating humidifiers and reducing system cost and footprint.

Innovative Integrated End Plate

End plate with built-in hydrogen ejector and three-chamber sensor reduces external piping by 40% and leakage risk by 70%.

Optimized Thermal Control

Reuse of coolant outlet keeps in-stack temperature difference within ±3°C, improving stack consistency by 50%.

Proven Applications

Validated in A1H and A2 graphite stack products, ideal for high-reliability, long-duration power output scenarios.

48V 5kW Hydrogen Backup Power Technology

Release Date2025.08.06

Vision’s 48V 5kW hydrogen backup power technology is designed for telecom base stations and various DC load applications, combining high efficiency, modularity, and intelligent control. The system adopts a fully modular design for flexible deployment and easy expansion, supporting both local and remote control to enhance operational flexibility and reliability. This technology has been successfully applied to multiple 48V 5kW hydrogen backup power products, providing safe, stable, and clean energy for next-generation green communication infrastructure.

Advantages

High Deployment Flexibility

Supports rapid on-site installation and functional combination to fit different backup power needs.

Intelligent Control System

Equipped with a local HMI and remote supervisory control for system start/stop and real-time monitoring.

Green & Low-Carbon

Powered by hydrogen with zero carbon emissions, aligning with low-carbon communication trends.

Wide Application Adaptability

Ideal for remote areas, extreme climates, and off-grid telecom sites or emergency backup scenarios.

High System Efficiency

Overall operating efficiency exceeds 50%, improving hydrogen utilization.

Modular Cabinet Design

Cabinet-based modular architecture supports customization for telecom base stations and various DC loads.

10kW Combined Heat and Power (CHP) System Technology

Release Date2025.08.06

Vision’s 10kW CHP system integrates power generation and heat supply, featuring high energy utilization, modular design, and intelligent control. Suitable for residential, commercial, and industrial applications, it uses high-efficiency fuel conversion to achieve over 85% total energy efficiency. The system supports both local and remote smart management, offering a green, flexible, and reliable distributed energy solution. It has been successfully applied in multiple 10kW CHP products.

Advantages

Multi-Function in One Unit

Provides both electricity and heat, adaptable to residential, industrial, and commercial scenarios.

Intelligent Control System

Supports on-site HMI operation and remote supervisory control for easy start/stop and monitoring.

High Reliability Design

Proven system architecture ensures stable operation for long-term continuous use.

Green Distributed Energy

Compatible with clean energy sources, enabling low-carbon buildings and smart energy applications.

High Total Energy Efficiency

Coordinated power and heat generation achieves over 85% total energy utilization.

Flexible Modular Design

Cabinet-based modular structure supports multi-functional configurations, easy deployment, and maintenance.