SolutionsMotive Power

Overview

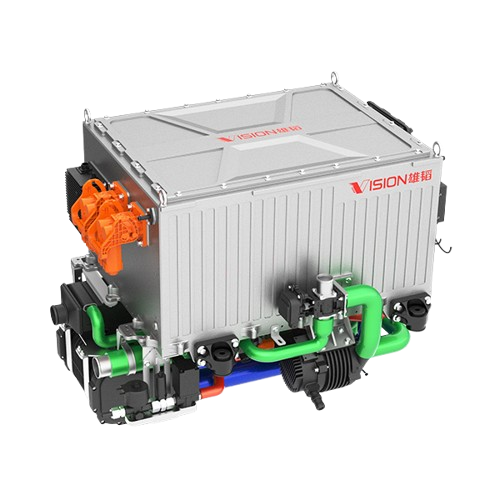

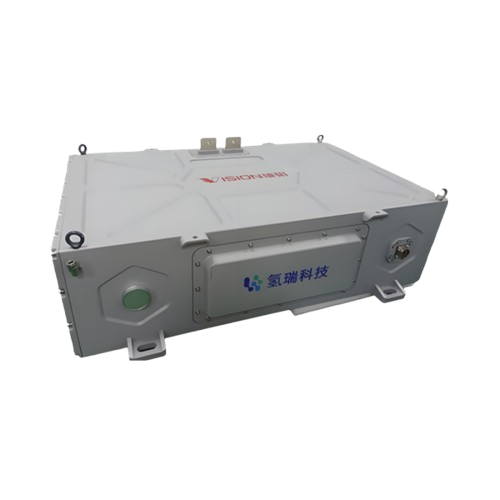

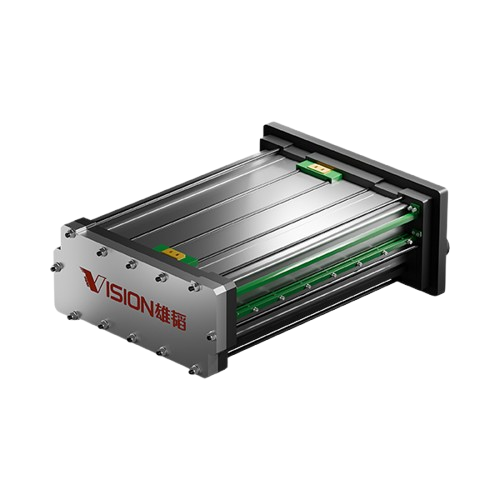

Vision powers material handling and traction equipment—including forklifts, aerial platforms, AGVs, pallet trucks, and sweepers, etc.—with modular lithium batteries engineered for demanding multi-shift operations. Our high-capacity systems drive heavy-duty industrial applications, featuring robust safety architecture and cloud-connected intelligence for operational oversight. Validated through global industrial partnerships, Vision batteries deliver consistent performance exceeding 3,500 full cycles in extreme conditions. From warehouse logistics to construction sites, we provide resilient power solutions built to withstand rigorous daily use without compromise.

Advantages

-

Smart Management Module with Real-Time Monitoring

- Built-in BMS enables real-time battery status tracking and early fault prevention.

Smart Management Module with Real-Time Monitoring

Smart Management Module with Real-Time Monitoring -

High Safety & Wide Temperature Adaptability

- Stable performance under extreme conditions ensures equipment safety.

High Safety & Wide Temperature Adaptability

High Safety & Wide Temperature Adaptability -

Reusable & Pollution-Free

- Eco-friendly design supports sustainability with recyclable materials.

Reusable & Pollution-Free

Reusable & Pollution-Free -

Long Cycle Life

- Durable and reliable for frequent, long-term use, reducing replacement costs.

Long Cycle Life

Long Cycle Life

Customer Value

-

Early fault warning for simplified maintenance and management

Early fault warning for simplified maintenance and management -

Stable operation under extreme climates or complex conditions, ensuring business continuity

Stable operation under extreme climates or complex conditions, ensuring business continuity -

Supports environmental responsibility, meets green procurement standards, and enhances corporate image

Supports environmental responsibility, meets green procurement standards, and enhances corporate image -

Reduces replacement frequency and maintenance costs, minimizing downtime and maximizing ROI

Reduces replacement frequency and maintenance costs, minimizing downtime and maximizing ROI

Application Scenarios

-

01Lithium Battery Solution for ForkliftsDesigned for electric forklifts, stackers, and other logistics equipment, featuring high energy density and fast charging for long-duration operation. Enhances warehousing and handling efficiency while reducing maintenance and replacement costs.

01Lithium Battery Solution for ForkliftsDesigned for electric forklifts, stackers, and other logistics equipment, featuring high energy density and fast charging for long-duration operation. Enhances warehousing and handling efficiency while reducing maintenance and replacement costs. -

02Lithium Battery Solution for Golf CartsSpecifically built for golf carts, combining a lightweight structure with stable discharge performance. Delivers smooth driving and long-lasting power, supporting efficient operation in golf courses, resorts, and parks.

02Lithium Battery Solution for Golf CartsSpecifically built for golf carts, combining a lightweight structure with stable discharge performance. Delivers smooth driving and long-lasting power, supporting efficient operation in golf courses, resorts, and parks. -

03Lithium Battery Solution for Aerial Work PlatformsApplied in scissor lifts, boom lifts, and other aerial equipment. Delivers high safety and stability, ensuring reliable operation even in complex work environments—supporting efficient and low-carbon construction.

03Lithium Battery Solution for Aerial Work PlatformsApplied in scissor lifts, boom lifts, and other aerial equipment. Delivers high safety and stability, ensuring reliable operation even in complex work environments—supporting efficient and low-carbon construction.

FAQs

-

qHow to properly store batteries?aTo ensure safety and extend battery life, follow these guidelines:

1. Environment: Store in a dry, cool, and well-ventilated place. Avoid direct sunlight and heat sources. Recommended temperature: 5°C–25°C; humidity: 45%–75%.

2. Charge level:

-Lead-acid: Fully charge before storage; recharge every 3 months.

-Lithium: Store at 30%–60% charge; check voltage every 6 months and recharge if needed.

3. Safety: Prevent short circuits by insulating terminals. Keep away from metal objects. Avoid drops and strong impacts.

4. Separation: Clearly label and separate new and used batteries. Recycle used batteries promptly.

5. Packaging: Use original or insulated packaging to protect from dust, moisture, and physical damage. -

qWhat should be noted when transporting batteries?aEnsure batteries pass UN38.3 testing before shipment, use shockproof and short-circuit-proof packaging with proper labeling. Lithium batteries for air transport must not exceed 30% charge and require complete transport documentation. Damaged or swollen batteries are prohibited from transport.

Contact Us

Want to learn more about Vision's industry solutions?

Leave your contact information and our sales team will get in touch with you shortly.

-

Name

Name -

Tel

Tel -

Email

Email -

CountryPlease selectAfghanistan Albania Algeria Andorra Angola Antigua and Barbuda Argentina Armenia Australia Austria Azerbaijan Bahamas Bahrain Bangladesh Barbados Belarus Belgium Belize Benin Bhutan Bolivia Bosnia and Herzegovina Botswana Brazil Brunei Bulgaria Burkina Faso Burundi Cabo Verde Cambodia Cameroon Canada Central African Republic Chad Chile China Colombia Comoros Congo (Congo-Brazzaville) Costa Rica Croatia Cuba Cyprus Czech Republic (Czechia) Democratic Republic of the Congo Denmark Djibouti Dominica Dominican Republic Ecuador Egypt El Salvador Equatorial Guinea Eritrea Estonia Eswatini Ethiopia Fiji Finland France Gabon Gambia Georgia Germany Ghana Greece Grenada Guatemala Guinea Guinea-Bissau Guyana Haiti Honduras Hungary Iceland India Indonesia Iran Iraq Ireland Israel Italy Jamaica Japan Jordan Kazakhstan Kenya Kiribati Kuwait Kyrgyzstan Laos Latvia Lebanon Lesotho Liberia Libya Liechtenstein Lithuania Luxembourg Madagascar Malawi Malaysia Maldives Mali Malta Marshall Islands Mauritania Mauritius Mexico Micronesia Moldova Monaco Mongolia Montenegro Morocco Mozambique Myanmar (Burma) Namibia Nauru Nepal Netherlands New Zealand Nicaragua Niger Nigeria North Korea North Macedonia Norway Oman Pakistan Palau Palestine Panama Papua New Guinea Paraguay Peru Philippines Poland Portugal Qatar Romania Russia Rwanda Saint Kitts and Nevis Saint Lucia Saint Vincent and the Grenadines Samoa San Marino Sao Tome and Principe Saudi Arabia Senegal Serbia Seychelles Sierra Leone Singapore Slovakia Slovenia Solomon Islands Somalia South Africa South Korea South Sudan Spain Sri Lanka Sudan Suriname Sweden Switzerland Syria Taiwan Tajikistan Tanzania Thailand Timor-Leste Togo Tonga Trinidad and Tobago Tunisia Turkey Turkmenistan Tuvalu Uganda Ukraine United Arab Emirates United Kingdom United States Uruguay Uzbekistan Vanuatu Vatican City Venezuela Vietnam Yemen Zambia Zimbabwe

CountryPlease selectAfghanistan Albania Algeria Andorra Angola Antigua and Barbuda Argentina Armenia Australia Austria Azerbaijan Bahamas Bahrain Bangladesh Barbados Belarus Belgium Belize Benin Bhutan Bolivia Bosnia and Herzegovina Botswana Brazil Brunei Bulgaria Burkina Faso Burundi Cabo Verde Cambodia Cameroon Canada Central African Republic Chad Chile China Colombia Comoros Congo (Congo-Brazzaville) Costa Rica Croatia Cuba Cyprus Czech Republic (Czechia) Democratic Republic of the Congo Denmark Djibouti Dominica Dominican Republic Ecuador Egypt El Salvador Equatorial Guinea Eritrea Estonia Eswatini Ethiopia Fiji Finland France Gabon Gambia Georgia Germany Ghana Greece Grenada Guatemala Guinea Guinea-Bissau Guyana Haiti Honduras Hungary Iceland India Indonesia Iran Iraq Ireland Israel Italy Jamaica Japan Jordan Kazakhstan Kenya Kiribati Kuwait Kyrgyzstan Laos Latvia Lebanon Lesotho Liberia Libya Liechtenstein Lithuania Luxembourg Madagascar Malawi Malaysia Maldives Mali Malta Marshall Islands Mauritania Mauritius Mexico Micronesia Moldova Monaco Mongolia Montenegro Morocco Mozambique Myanmar (Burma) Namibia Nauru Nepal Netherlands New Zealand Nicaragua Niger Nigeria North Korea North Macedonia Norway Oman Pakistan Palau Palestine Panama Papua New Guinea Paraguay Peru Philippines Poland Portugal Qatar Romania Russia Rwanda Saint Kitts and Nevis Saint Lucia Saint Vincent and the Grenadines Samoa San Marino Sao Tome and Principe Saudi Arabia Senegal Serbia Seychelles Sierra Leone Singapore Slovakia Slovenia Solomon Islands Somalia South Africa South Korea South Sudan Spain Sri Lanka Sudan Suriname Sweden Switzerland Syria Taiwan Tajikistan Tanzania Thailand Timor-Leste Togo Tonga Trinidad and Tobago Tunisia Turkey Turkmenistan Tuvalu Uganda Ukraine United Arab Emirates United Kingdom United States Uruguay Uzbekistan Vanuatu Vatican City Venezuela Vietnam Yemen Zambia Zimbabwe -

Company

Company

Information

Information