News

Sneak preview of the new VISTAH-130E, Vision Hydrogen Team plans to reduce hydrogen consumption by 30% by 2025

As more vehicles are actually installed, Vision has found that fuel cell engines still need to improve efficiency, which can fully guarantee the economy of long-distance transport. Therefore, the main research directions of Vision Hydrogen fuel cell team are currently reducing auxiliary power consumption and reducing system hydrogen consumption by 30% in two major areas.

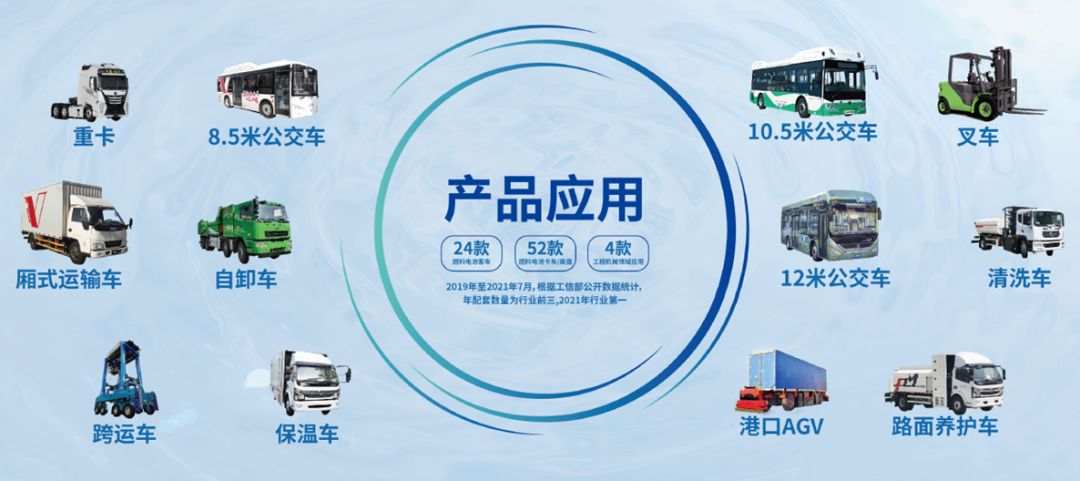

At present, hydrogen energy applications are still dominated by fuel cell vehicles, and after 2025, hydrogen energy vehicles will grow exponentially. Vision Hydrogen fuel cell team's industry chain has a wide range of applications, mainly for vehicles, with products ranging from 30kW to 130kW, basically covering all hydrogen vehicles on the market, from buses, sanitation vehicles and heavy trucks. So far in 2018,Vision Hydrogen fuel cell team has developed and supported over 400 hydrogen vehicles with a mileage of 13 million km.

Demand-driven, technology-led

The idea of Xiongtao Hydroxiong's product development is market-driven, based on customer demand, the system application is made into a solution, imported into the technical department, and developed into a product. At the same time, in response to the low temperature start problem of hydrogen fuel cells, Vision Hydrogen fuel cell team has made low temperature start a professional algorithm module for hydrogen fuel cells, adding this function to help the system achieve a fast low temperature start of -30 degrees.

With the increase in the number of hydrogen vehicles produced, the hydrogen fuel cell system is not very stable. In response to this problem, Vision Hydrogen fuel cell team has an internal big data platform that enables it to understand the relevant conditions of the hydrogen vehicles through its mobile phone, including the temperature and pressure of the hydrogen fuel cell during operation.

New product preview

At the conference, Dr. Tang Tingjiang presented the latest generation of VISTAH-130E from Vision Hydrogen fuel cell team, which has the following four main features.

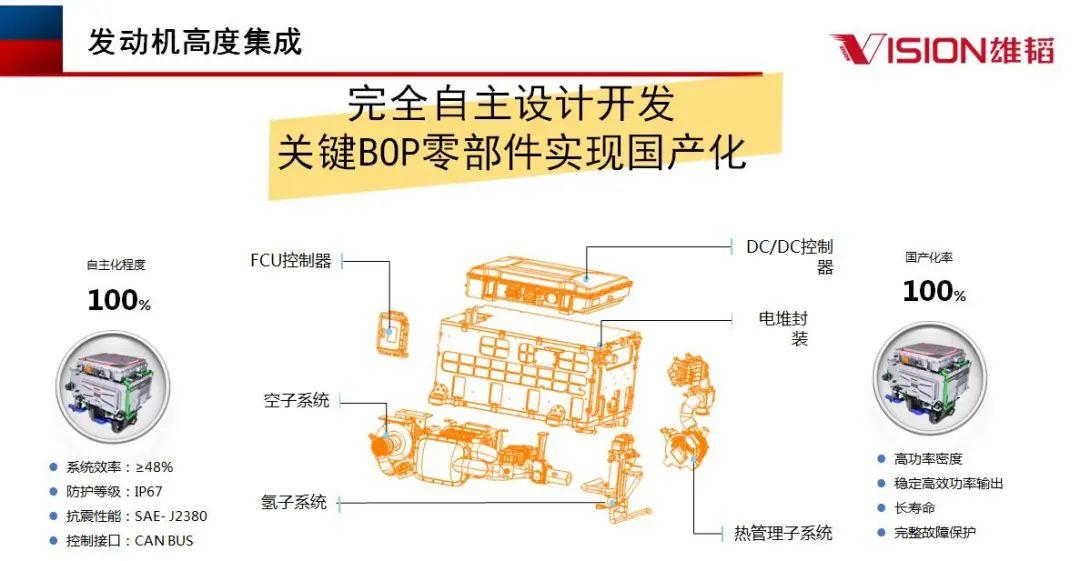

Highly integrated components: integrated hydrogen subsystem, integrated humidifier intercooler

Highly integrated system: integrated controller, highly integrated water-hydrogen-air subsystem; high power consumption near the system.

High efficiency, low hydrogen consumption: equipped with self-developed pilot, reducing power consumption near the system

Adaptive altitude: closed-loop air control, adaptive adjustment of the full power band supercharger.

Dr. Tang Tingjiang said that Vision Hydrogen fuel cell wants the system to achieve localisation of key BOP components as far as possible under the premise of completely independent design and development, and to steadily advance through small batch demonstration operations in order to achieve localisation of key BOP components.

Reducing costs and hydrogen consumption

At the moment, Vision Hydrogen fuel cell team has made efficiency improvement a major internal research direction, firstly by demanding a reduction in auxiliary power consumption and secondly by increasing hydrogen utilisation as much as possible, bringing the new system efficiency up to a planned 55% or more.

Then the problem of hydrogen consumption, which is closely related to efficiency, is also inevitable. Vision Hydrogen fuel cell team plans to reduce hydrogen consumption by 30% in 2025 compared to 2022, to achieve the ultimate hydrogen consumption leading the world.

Faced with the problem of hydrogen consumption, how to achieve effective reduction to reach the target? Dr. Tang Tingjiang said there are five aspects.

Increasing the power of the reactor

Reducing auxiliary power consumption

Improving hydrogen utilisation

Thermal management and energy management of the whole vehicle

User side usage

In the future, Vision Hydrogen fuel cell team will continue to develop its own pilot and distributor for the core components, while for high altitude areas, the system will adopt the method of closed-loop control algorithm to make the product meet the relevant requirements of the region.

Finally, on the issue of how to promote and use hydrogen energy products, Dr. Tang Tingjiang pointed out that the following three points should be achieved: high quality, high cost performance and high safety; customer-oriented quality delivery guarantee; and making engine products that customers can afford and use with confidence.