News

Dr. Tang Tingjiang: Building core competencies based on fuel cell system pain points to achieve comprehensive cost reduction

"A comprehensive cost reduction program for fuel cell engine products should work on four aspects: cost reduction of core components, cost reduction of design optimization, cost reduction of scale manufacturing, and cost reduction of laddering utilization. The cost reduction will be reduced by 25%-30% per year." Dr. Tang Tingjiang, R&D Director of Shenzhen HydraV Fuel Cell Co., Ltd., said at the 2022 (4th) GaoGong Hydrogen Power Industry Summit (South China Station) event.

On May 31-June 1, 2022, the (4th) Gaogong Hydrogen Industry Summit (South China Station) was successfully held, and Dr. Tang Tingjiang made a wonderful sharing (the following is a selection of his speech).

Product application pain points and solutions

Current hydrogen products are facing relatively poor stability, high product acquisition and usage costs. Based on the application pain points of fuel cell products, we have done some reflections. At the design end, we must make standardised products. In order to meet the needs of different car companies, we should consider developing products on the same platform and make the interface for product standardisation. In this way, product design and even after-sales service at the back end will be quite convenient, and the cost will also be relatively controllable.

At the product development end of things, we have to put a lot of importance on experimentation. It's easy to make a system out of it, and it's easy to generate power, but it's actually a very complicated thing to actually do all the experiments on the system. We will not develop too many models of systems, but we will do all the experimental verification of the developed systems, including low temperature start-up, vibration test, salt spray test, and also the life time test which we attach great importance to, etc. After a series of severe experiments, then let the systems that meet the relevant standards be put on the market.

Engine products using core components to reduce costs, laddering to reduce costs, design optimisation to reduce costs and scale manufacturing to reduce costs are expected to cost less than RMB1,000/kW in 2025, with an average annual cost reduction of 25%-30%.

Shenzhen HydraV Fuel Cell Co., Ltd. Engine products and application results

The Shenzhen HydraV Fuel Cell Co., Ltd. fuel cell engine system achieves full coverage from 30kW to 130kW. Not long ago, the Hubei Provincial Hydrogen Energy Demonstration Heavy Truck equipped with Vision Group's 130kW fuel cell engine was put into operation.

At present, Shenzhen HydraV Fuel Cell Co., Ltd. has matched 20 fuel cell buses, 47 fuel cell trucks/chassis and 4 models for application in the field of construction machinery into the announcement catalogue of the Ministry of Industry and Information Technology, and another 70 fuel cell vehicles are being delivered.

The road to product and technology independence and sustainability

Full power coverage of the Vision hydrogen male fuel cell engine system, focusing on building core competencies. Project acquisition and management are closely focused on business hotspots; the trinity of industry, academia and research to enhance core competencies.

Our engines have reached the point where being able to generate electricity is not the main goal, but rather placed on improving efficiency. Although the latest national testing standards do not say what the efficiency must be, we want to improve the efficiency of the engine as much as possible.

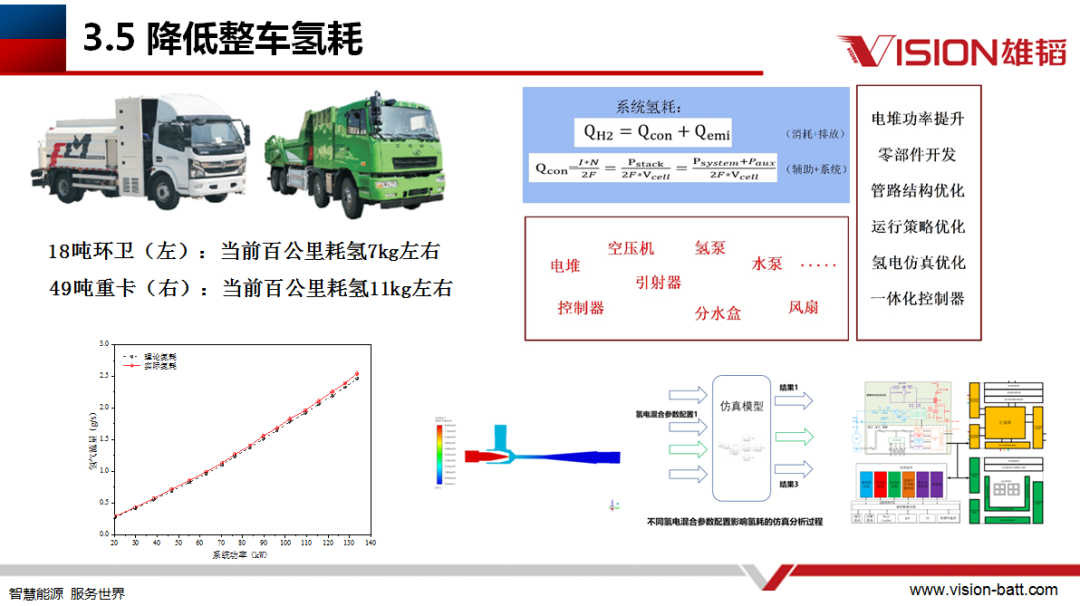

Reducing hydrogen consumption is actually combined with improving efficiency. It is also important to reduce hydrogen consumption if fuel cell vehicles are to develop in the long term. Vision Group has made the reduction of hydrogen consumption its main task and has done a lot of research: at present, the hydrogen consumption of 18-ton sanitation vehicles is about 7 kg per 100 km; the hydrogen consumption of 49-ton heavy trucks is about 11 kg per 100 km, which is very effective.

From the actual operation situation, at present, a total of 390 fuel cell vehicles, including buses, heavy trucks and logistics, are in operation nationwide, with a total driving distance of over 13 million kilometres and a total emission reduction of 22 million kilograms, which is equivalent to planting more than 150,000 trees.

In the future, Shenzhen HydraV Fuel Cell Co., Ltd. will work with industry chain partners to help the development of high-quality hydrogen energy industry!