News

2 minutes to learn about the 100-year history of forklifts

The forklift truck originated in the United States and was developed in Japan, started late in China but developed rapidly.

Hong Kong people like to call it a forklift, while the Taiwanese call it a forklift. Of course, the most widely known name has to be forklift.

Forklifts are widely used in warehouses, factories, ports, airports and other scenarios as efficient equipment for stacking, loading and unloading and short-distance transportation, greatly improving labour productivity and playing an important role in economic development. In short, the history of forklifts and the economic development curve refract each other.

Birth and development of the forklift truck

After the First World War, mechanical designers seeking to increase the productivity of warehouse operations were inspired by the advantages of stacking as opposed to simply moving goods horizontally, creating a platform truck with 'high lifting power'.

In the early 1920s, a similar product was created with an electric forklift truck, followed by a forklift truck with a petrol engine and lifting mechanism.

The forklift truck has been born and has undergone a century of changes, and now it has won the center position and become an indispensable equipment in the process of production and warehouse operation.

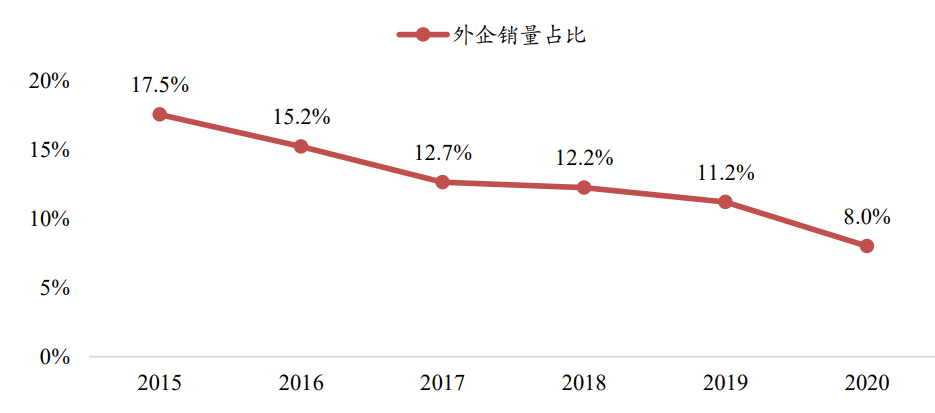

The information shows that after years of technical accumulation and continuous investment in R&D, domestic brands are gradually on par with the international industry level in terms of product series completeness, technical quality management and high cost performance, and the market share of overseas brands in the country will drop to less than 10% between 2015 and 2020.

Types of forklift trucks

The World Industrial Vehicle Association (WITS) classifies and categorises forklifts into four categories based on power type, working environment, operator position and equipment attributes. The China Industrial Vehicle Association (CITA) joined WITS in 2001 and is in line with the world in terms of statistical calibre.

The four categories of forklift trucks mainly include: Class I electric counterbalanced forklift trucks, Class II electric ride-on warehouse forklift trucks, Class III electric pedestrian warehouse forklift trucks and Class IV/V internal combustion counterbalanced forklift trucks.

Among them, electric forklift trucks refer to the batteries that provide all the energy required by the forklift trucks. These include: lead-acid batteries, lithium batteries and hydrogen fuel cells.

Forklift trucks now

At present, lithium batteries are widely used in the global forklift industry due to their many advantages such as high energy density, small size, maintenance-free, fast charging and long service life. The penetration rate of new energy forklifts such as zero-carbon emission hydrogen fuel also continues to grow.

The total sales volume of lithium electric forklifts in China reached 333,000 units in 2021, an increase of 106.3% year-on-year; among them, the domestic sales volume was 151,000 units, an increase of 58.6% year-on-year; the export sales volume was 182,000 units, an increase of 175.1% year-on-year. These figures fully illustrate that lithium battery forklifts are widely recognized by the market, and the electrification, new energy and intelligence of forklifts are becoming new highlights.

Along with the new energy revolution, forklifts are changing from lead-acid batteries to lithium batteries and hydrogen fuel cells, from traditional to intelligent, and from rough management to fine management.

Vision power & forklift lithium battery new energy solutions are the protective power of intelligent green handling, matching the efficient operation requirements of time and space in modern warehousing and other forklift operation places. Vision power lithium battery is safe, efficient, with higher energy conversion efficiency, supporting long time operation and making full use of every second.

The future of forklifts

In recent years, a number of hydrogen fuel cell forklifts have appeared in the public eye. For a while, hydrogen-fuelled forklifts have become a new hit. Advantages such as zero emission, long range, fast hydrogen refuelling and low noise have made forklift manufacturers excited.

The three verticals and three horizontals in the New Energy Vehicle Industry Development Plan (2021-2035), "three verticals" means pure electric vehicles, plug-in hybrid and fuel cell vehicles.

Because of the obvious advantages, forklift leaders are now laying out, and hydrogen fuel cell forklifts will definitely be the main direction of forklift transformation in the future.

At a time when industries are becoming more and more concerned about the impact of production on the environment and society, Vision hydrogen energy can help companies achieve true zero carbon emissions in the forklift segment.

Vision's hydrogen forklift battery solution has low working environment requirements, good temperature adaptability, long service life, high reliability, continuous operation under sufficient hydrogen supply, easy maintenance and servicing, green and environmentally friendly, and relatively small size for easy storage and transportation. It is the preferred solution for promoting and practising low carbon production.

Looking back over the centuries, forklifts have started as simple mechanical devices, have undergone several innovations and are now being brought into a smarter era by the wave of information technology in society. Technological innovation is accelerating and hardware and software are rapidly iterating. It is predictable: the next generation of forklifts will be smarter and greener.